Monday 19th

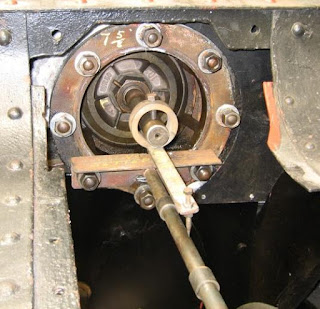

Gilbert supplied the following photos of the timing gadget that was used on 2807 up at Llangollen (and that David is replicating as homework):

Wednesday 21st

Peculiar day. Things seemed to go rather slowly. Bruce & Gilbert spent most of the day removing sand from the sandboxes. Various difficulties: the delivery pipe is close to the rail, which means that you can’t get much of a receptacle beneath it to catch the sand; damp sand does not flow at all; the front right delivery tube was blocked by some oily mud! How on earth that got in there defies imagination.

Getting the sand out requires long, flexible arms! Even when you reach in and try to stir the final grains around, they hide in corners. The only way to get them all out is by using the “hoover”. Bruce demonstrates how. Mike [Loco Dept] helped, but slid swiftly out of camera shot when he saw me …

Tim P [Loco Dept] and a small gang of cleaners cleaned up the running boards and various bits in the cab.

John G had also continued polishing brassware in the cab. But he’d started the day by painting the

chairs in the production line - five primed tops plus two black bottoms. The latter two were those

that I ran out of enthusiasm for wire-brushing last time … so had to do it this time.

During the afternoon, I attacked the pile of “stuff” in the van that we are squatting in. I’m fed up

with trying to paint boot scrapers that are continually wet (in the container). No sooner do I dry one

off, than I breathe out and moisture condenses all over it again! So, I’m determined to make room

in the van to do the painting! It’s a former brake van, made of wood, so is significantly warmer than

the 20ft sea container. By end of play, I had cleared one side sufficiently to use as a painting

workbench.

2807 is scheduled to be back in service on Saturday and Monday onwards.

Late news: 7820 broke a spring in service today! Also, 4270 ran out of steam just outside Greet

Tunnel! The coal got the blame for the latter - the grate was jammed with clinker. As a result of the

Manor’s failure, 2807 was prepared for service on Thursday.

Thursday 22nd

Allegedly, 2807 was still rather cool on Thursday morning, as the warming fire had not been as effective as one would expect. The coal got the blame (again), but I think Carpo’s out of practice at lighting warming fires! ;-)

Nevertheless, “old faithful” got going and did what was asked of her.

As an aside: the café completely sold out of boot scrapers - and I had none with which to restock.

There were a few issues, this being her first day back in service after the tube replacement and boiler washout:

- three mudhole doors were hissing steam;

- steam was whisping from the bottom of the Mason’s valve;

- steam was leaking between the top manifold and the whistle;

- the lubricator was very slow.

At the end of the day, Carpo reported: “I'm pleased to report that having just inspected her on the pit

all seems to be well with the boiler and I will ask tomorrow’s crew to make sure that they carefully

inspect before lighting. The right hand rod piston packing has blown however and this will need to be

looked at sooner rather later.”

Friday 23rd

Ah well; win a few, lose a few: Carpo reported, “I'm afraid I had to fail 2807 [Friday] night due to an element leak. Investigation this [Saturday] morning has revealed that the two elements put back in after the tube replacement appear to be leaking at the header on the spherical joint. This is disappointing as it was ok at the steam test and was ok for most of the day before yesterday although the driver thought something start to go amiss in the afternoon but we couldn't see anything wrong upon examination that evening. It got worse to a point yesterday, but the crew were able to continue till the end of the day.”

Saturday 24th

Gilbert & I arrived to find Carpo and Sam inside the smokebox, having pulled out one of the superheater elements. They cleaned the surfaces and seats; replaced the clamp (which clearly has been well used) and fitted the element back in place.

Gil was given the privilege of playing with the regulator, while Carpo watched the steam still

squeezing out of the joint! The next attempt was to use a “copper” in one side of the clamp to try to

force that side to close more tightly. That didn’t work. Gil found a tin of Green Hematite (jointing

compound), so Carpo smeared some of that on the end of the element. Gil exercised his right arm

again, and still the seal was not 100%. However, Carpo moved on to the second element and

repeated the fix.

Apart from the four of us, Toddington was deserted. Carpo was supposed to be driving the Manor, I

believe, so it was extremely kind of him to give that up for the morning. He then changed and went

to resume his rostered duty; Gil buzzed off to Winchcombe for a while, and Sam & I lit a fire.

Carpo’s plan was to raise pressure and test the elements when he got back at the end of the day (in

the dark!). We got her up to 190 psi by 5.15 pm, when I had to disappear. We then anxiously

awaited the outcome ….

… George [Loco Dept] turned up in time to assist Carpo in testing the fix. He declared it a pass!

Monday 26th

Just as I arrived at Winchcombe station to check the boot scraper stock level, 2807 pulled in from

Cheltenham. Phew. Something of a relief!

Roger

No comments:

Post a Comment