Wednesday 28th

Maybe it was the left-overs from Christmas, but none of us was terribly enthusiastic about tackling a big job. I couldn’t even face getting the equipment out and cleaning more rail chairs. Besides, there’s less than a week to go!

Nevertheless, John G applied a coat of Deproma to the two remaining chairs in the production line. I fitted a brush to the last ordered boot scraper. Later, John and also Ray applied some Cuprinol to a dozen or more brush heads.

Ray, Gil and Bruce had started the day at Winchcombe because the old pillar drill had died but Ray had found a willing taker! So, they had been there removing the drill from the siphon van and into the taker’s van.

JC [Loco dept] said that he would get a couple of chaps to light a warming fire in preparation for 2807 being in service on Thursday and Friday, so we left them to it.

Gil decided to read through the issues log to see what we could attend to. He and Bruce removed the bottom of the Mason’s valve, which reportedly was leaking steam. They then tightened up the nut holding the left-hand whistle to its steam supply - which Sam and I had noticed was leaking when we lit the warming fire last week. While up there, Bruce discovered our retractable rule that must have been sat on top of the firebox since Bruce was last up there (3 operating days ago).

I think Gil must have spread grease around somewhere, because I got red grease on my glove!

Bruce, being concerned that the pivots in the other compensating beams are seized, attempted to

persuade some oil to seep between the pin, bush and beams.

Ray and I investigated an older reported issue that, after we had fitted new brake blocks, the tender

brakes were dragging. A couple of them are still fairly tight, but not dragging as such. There is no

sensible way of adjusting the brakes individually. One would have to heat the rods that link one to

another, and either stretch or compress (as appropriate) to effect an adjustment. Alternatively, you

just wait until they settle themselves in!

We all decided that there were things that we could be doing elsewhere, and knocked off early.

Thursday 29th

I checked that 2807 was operating. She was.

The Deproma that John had applied to the two rail chairs was still tacky, but I put an enamel top coat

on anyway.

Friday 30th

I intended doing the lettering on the chairs, but could see that I had missed quite a few spots, so had

to touch-up the enamel instead. I then cut some wedges for the boot scraper brushes. I prefer to

do this when nobody else is around - operating the band saw with people walking in, out and behind

is a bit of a health hazard, methinks!

Met Gilbert as I left. He’d been for a ride on the footplate. Nothing amiss.

Saturday 31st

Bruce and I turned up, though both of us had other things to do elsewhere. So, after checking the

issues log, and inspecting a couple of points, we knocked off at lunch time. The remaining issues are:

01: [JC]: Excessive side play in all gradient pins. Serviceable until rods overhauled. {This was reported in June 2015, would you believe! We were too busy to attend to this last winter. Time to take a look this winter?}

15: [JC]: Tender rear RH brake grease nipple loose. Replaced but cannot tighten up. {Reported in

May, we know that the thread has gone, and it may need a sleeve fitting to rectify this.}

31: [PG]: J cocks stuck. {Reported in July, it doesn’t say which J-cocks! Gilbert believes it is one feeding steam to the hydrostatic lubricator. We’ll have to examine it and see.}

34: [PG]: Balance weight rivets loose on LH driver / LH trailing driver, RH driving wheel. {We had

marked this to review during winter maintenance. It’s a challenge to know how to tighten these rivets, as access is very limited behind them.}

41: [PG]: Top valve on gauge frame blowing. {See photo. Valve needs repacking.}

47: [JC]: RH piston gland blowing. {Carpo had suggested that it settled down while in service. Gilbert noted to monitor this, but we ought to repack it over winter.}

48: [JC]: LH front and rear top mudhole doors + RH front top mudhole door blowing. {Carpo marked

this to be monitored. I wondered if the inside surfaces had not been cleaned when the seals were

replaced a couple of weeks ago?}

52: [SB]: Leading coupled springs hitting pony truck pivot beam. {You have to be pretty keen to spot that! Actually, the dent (arrowed) is on the frame stretcher, not the pivot beam. Note that it is not shiny, which may imply that it doesn’t happen all of the time. Bruce and I took a look and decided that the only solution would be to put additional weight onto the pony wheels. Bruce dug out the weights, and each pony wheel currently takes 3.4 tons. We think that they ought perhaps take more, but there is no weight diagram specifically for our loco due to the fact that it has been modified so many times over the years.}

53: [SB]: Rear damper door warped. (Coat caught fire oiling up!!!)

54: [PG]: Safety valves lifting well before red line. {Note the red line. 😊}

She was still warm from yesterday, which is why there is still 15 psi “on the clock”. Bruce had a play with the piston rod lubricators, because I noticed a pool of oil on the top of it, and then discovered water running out when I waggled it!

We should examine these and see if the felt pads are soaked with water, and make sure they are rubbing on the piston rod.

Apart from finishing the two boot scrapers in the production line, we called it a day: New Year’s Eve

day! The team sends its best wishes to all of our supporters, and we hope that 2017 brings you your

fair share of happiness, success and good fortune.

Roger

Saturday, 31 December 2016

Tuesday, 27 December 2016

Maintenance Update (timing, sand, faithful, clamp)

Monday 19th

Gilbert supplied the following photos of the timing gadget that was used on 2807 up at Llangollen (and that David is replicating as homework):

Wednesday 21st

Peculiar day. Things seemed to go rather slowly. Bruce & Gilbert spent most of the day removing sand from the sandboxes. Various difficulties: the delivery pipe is close to the rail, which means that you can’t get much of a receptacle beneath it to catch the sand; damp sand does not flow at all; the front right delivery tube was blocked by some oily mud! How on earth that got in there defies imagination.

Getting the sand out requires long, flexible arms! Even when you reach in and try to stir the final grains around, they hide in corners. The only way to get them all out is by using the “hoover”. Bruce demonstrates how. Mike [Loco Dept] helped, but slid swiftly out of camera shot when he saw me …

Tim P [Loco Dept] and a small gang of cleaners cleaned up the running boards and various bits in the cab.

John G had also continued polishing brassware in the cab. But he’d started the day by painting the

chairs in the production line - five primed tops plus two black bottoms. The latter two were those

that I ran out of enthusiasm for wire-brushing last time … so had to do it this time.

During the afternoon, I attacked the pile of “stuff” in the van that we are squatting in. I’m fed up

with trying to paint boot scrapers that are continually wet (in the container). No sooner do I dry one

off, than I breathe out and moisture condenses all over it again! So, I’m determined to make room

in the van to do the painting! It’s a former brake van, made of wood, so is significantly warmer than

the 20ft sea container. By end of play, I had cleared one side sufficiently to use as a painting

workbench.

2807 is scheduled to be back in service on Saturday and Monday onwards.

Late news: 7820 broke a spring in service today! Also, 4270 ran out of steam just outside Greet

Tunnel! The coal got the blame for the latter - the grate was jammed with clinker. As a result of the

Manor’s failure, 2807 was prepared for service on Thursday.

Thursday 22nd

Allegedly, 2807 was still rather cool on Thursday morning, as the warming fire had not been as effective as one would expect. The coal got the blame (again), but I think Carpo’s out of practice at lighting warming fires! ;-)

Nevertheless, “old faithful” got going and did what was asked of her.

As an aside: the café completely sold out of boot scrapers - and I had none with which to restock.

There were a few issues, this being her first day back in service after the tube replacement and boiler washout:

- three mudhole doors were hissing steam;

- steam was whisping from the bottom of the Mason’s valve;

- steam was leaking between the top manifold and the whistle;

- the lubricator was very slow.

At the end of the day, Carpo reported: “I'm pleased to report that having just inspected her on the pit

all seems to be well with the boiler and I will ask tomorrow’s crew to make sure that they carefully

inspect before lighting. The right hand rod piston packing has blown however and this will need to be

looked at sooner rather later.”

Friday 23rd

Ah well; win a few, lose a few: Carpo reported, “I'm afraid I had to fail 2807 [Friday] night due to an element leak. Investigation this [Saturday] morning has revealed that the two elements put back in after the tube replacement appear to be leaking at the header on the spherical joint. This is disappointing as it was ok at the steam test and was ok for most of the day before yesterday although the driver thought something start to go amiss in the afternoon but we couldn't see anything wrong upon examination that evening. It got worse to a point yesterday, but the crew were able to continue till the end of the day.”

Saturday 24th

Gilbert & I arrived to find Carpo and Sam inside the smokebox, having pulled out one of the superheater elements. They cleaned the surfaces and seats; replaced the clamp (which clearly has been well used) and fitted the element back in place.

Gil was given the privilege of playing with the regulator, while Carpo watched the steam still

squeezing out of the joint! The next attempt was to use a “copper” in one side of the clamp to try to

force that side to close more tightly. That didn’t work. Gil found a tin of Green Hematite (jointing

compound), so Carpo smeared some of that on the end of the element. Gil exercised his right arm

again, and still the seal was not 100%. However, Carpo moved on to the second element and

repeated the fix.

Apart from the four of us, Toddington was deserted. Carpo was supposed to be driving the Manor, I

believe, so it was extremely kind of him to give that up for the morning. He then changed and went

to resume his rostered duty; Gil buzzed off to Winchcombe for a while, and Sam & I lit a fire.

Carpo’s plan was to raise pressure and test the elements when he got back at the end of the day (in

the dark!). We got her up to 190 psi by 5.15 pm, when I had to disappear. We then anxiously

awaited the outcome ….

… George [Loco Dept] turned up in time to assist Carpo in testing the fix. He declared it a pass!

Monday 26th

Just as I arrived at Winchcombe station to check the boot scraper stock level, 2807 pulled in from

Cheltenham. Phew. Something of a relief!

Roger

Gilbert supplied the following photos of the timing gadget that was used on 2807 up at Llangollen (and that David is replicating as homework):

Wednesday 21st

Peculiar day. Things seemed to go rather slowly. Bruce & Gilbert spent most of the day removing sand from the sandboxes. Various difficulties: the delivery pipe is close to the rail, which means that you can’t get much of a receptacle beneath it to catch the sand; damp sand does not flow at all; the front right delivery tube was blocked by some oily mud! How on earth that got in there defies imagination.

Getting the sand out requires long, flexible arms! Even when you reach in and try to stir the final grains around, they hide in corners. The only way to get them all out is by using the “hoover”. Bruce demonstrates how. Mike [Loco Dept] helped, but slid swiftly out of camera shot when he saw me …

Tim P [Loco Dept] and a small gang of cleaners cleaned up the running boards and various bits in the cab.

John G had also continued polishing brassware in the cab. But he’d started the day by painting the

chairs in the production line - five primed tops plus two black bottoms. The latter two were those

that I ran out of enthusiasm for wire-brushing last time … so had to do it this time.

During the afternoon, I attacked the pile of “stuff” in the van that we are squatting in. I’m fed up

with trying to paint boot scrapers that are continually wet (in the container). No sooner do I dry one

off, than I breathe out and moisture condenses all over it again! So, I’m determined to make room

in the van to do the painting! It’s a former brake van, made of wood, so is significantly warmer than

the 20ft sea container. By end of play, I had cleared one side sufficiently to use as a painting

workbench.

2807 is scheduled to be back in service on Saturday and Monday onwards.

Late news: 7820 broke a spring in service today! Also, 4270 ran out of steam just outside Greet

Tunnel! The coal got the blame for the latter - the grate was jammed with clinker. As a result of the

Manor’s failure, 2807 was prepared for service on Thursday.

Thursday 22nd

Allegedly, 2807 was still rather cool on Thursday morning, as the warming fire had not been as effective as one would expect. The coal got the blame (again), but I think Carpo’s out of practice at lighting warming fires! ;-)

Nevertheless, “old faithful” got going and did what was asked of her.

As an aside: the café completely sold out of boot scrapers - and I had none with which to restock.

There were a few issues, this being her first day back in service after the tube replacement and boiler washout:

- three mudhole doors were hissing steam;

- steam was whisping from the bottom of the Mason’s valve;

- steam was leaking between the top manifold and the whistle;

- the lubricator was very slow.

At the end of the day, Carpo reported: “I'm pleased to report that having just inspected her on the pit

all seems to be well with the boiler and I will ask tomorrow’s crew to make sure that they carefully

inspect before lighting. The right hand rod piston packing has blown however and this will need to be

looked at sooner rather later.”

Friday 23rd

Ah well; win a few, lose a few: Carpo reported, “I'm afraid I had to fail 2807 [Friday] night due to an element leak. Investigation this [Saturday] morning has revealed that the two elements put back in after the tube replacement appear to be leaking at the header on the spherical joint. This is disappointing as it was ok at the steam test and was ok for most of the day before yesterday although the driver thought something start to go amiss in the afternoon but we couldn't see anything wrong upon examination that evening. It got worse to a point yesterday, but the crew were able to continue till the end of the day.”

Saturday 24th

Gilbert & I arrived to find Carpo and Sam inside the smokebox, having pulled out one of the superheater elements. They cleaned the surfaces and seats; replaced the clamp (which clearly has been well used) and fitted the element back in place.

Gil was given the privilege of playing with the regulator, while Carpo watched the steam still

squeezing out of the joint! The next attempt was to use a “copper” in one side of the clamp to try to

force that side to close more tightly. That didn’t work. Gil found a tin of Green Hematite (jointing

compound), so Carpo smeared some of that on the end of the element. Gil exercised his right arm

again, and still the seal was not 100%. However, Carpo moved on to the second element and

repeated the fix.

Apart from the four of us, Toddington was deserted. Carpo was supposed to be driving the Manor, I

believe, so it was extremely kind of him to give that up for the morning. He then changed and went

to resume his rostered duty; Gil buzzed off to Winchcombe for a while, and Sam & I lit a fire.

Carpo’s plan was to raise pressure and test the elements when he got back at the end of the day (in

the dark!). We got her up to 190 psi by 5.15 pm, when I had to disappear. We then anxiously

awaited the outcome ….

… George [Loco Dept] turned up in time to assist Carpo in testing the fix. He declared it a pass!

Monday 26th

Just as I arrived at Winchcombe station to check the boot scraper stock level, 2807 pulled in from

Cheltenham. Phew. Something of a relief!

Roger

Sunday, 18 December 2016

Maintenance Update (primer, stretcher, timing, painting)

Monday 12th

Unable to needle-gun rail chairs on Saturday due to rain, so had to pop down for an hour to clean two orders. Tripped the electricity in the box - don’t know why. Key to the power distribution board was not where it should have been, so I pulled out another plug and used that socket. Drill with wire brush attachment went on strike - loose or broken cable. No time to repair, so dumped it on the workbench and used another … At least these two chairs now have black bottoms.

Wednesday 14th

John G began by applying primer coat to the two rail chairs. I joined him in the container to paint the lettering on the chairs in the production line. John Mayell snook in, pinched the one black boot scraper and ran off with it. John G wrestled him to the ground and extracted the money for it.

Last week, John G had refitted the ferrules around the inspection plugs in the cab … except that (allegedly) Gilbert had lost one of the fixing bolts. John found one to fit and hence completed that task. As Head Painter, John was then tasked with slapping some black on those fitted bolt heads that David & John T completed last week. Thereafter, John G began to polish the brasswork in the cab, but ran out of polish and time.

During the removal of the spring compensating beam last week, Bruce had discovered that the piece of angle bracket to which a chain is attached (yellow arrow, left) was loose - though the nut was seized solid. The chain, by the way, is purely a safety measure: if the brake stretcher should break free (e.g. the nut fall of its end) the chain prevents the stretcher from fouling the rail/wheel/track.

Bruce struggled to find a spanner to fit the “standard” ¾” Whitworth nut; I think he filed the nut down to fit the spanner in the end (though he denied that that’s what he was doing … with the nut in the vice and the file in his hand …).

Gilbert went round spreading grease everywhere. Since this grease is coloured red, it’s a tad hard to disguise (see red arrows in photo).

Gil’s convinced that grease would not go into the nipples on the other three compensating beam pivots. I guess these will have to come off to see if these pivot pins have seized in their beams, too! A job for Winter Maintenance.

Saturday 17th

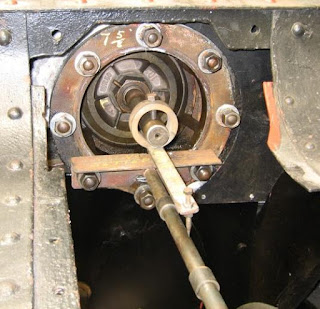

For his homework, David is making a gadget for measuring the valve timing. He brought the first

part in today to check the alignment of the holes. The first thing he discovered was that the studs

are not necessarily in exactly the same positions on different 28xx locos! So, he had to make the

holes a bit bigger.

The angle sits on three studs in the front of the valve chest (yellow arrows, right). This is just the first part. There will follow pieces that allow the movement of the valve rod to be monitored and marked. We will be able to determine what movement there is relative to the centre point, and hence if the valve is too far forwards or back. If it is, then steam will be let in (and also out) of the valve at lightly less than the optimum time.

I’ll keep you posted as more bits of the gadget are made.

After checking this, David played with our compressor for a while (neither of us spotting that the exhaust valve was wide open - which kind of limited the pressure that the compressor was able to build up!). Once up & running, David made up for lost time by needle-gunning seven rail chairs.

Meanwhile, Gilbert had been poring over diagrams (as is his wont), finally deciding that he would check the play in all of the coupling and connecting rods.

David (as if he had some fantastic control over the space-time over the continuum) also assisted Gil in taking some of those measurements.

I, on the other hand, could only be in one place at a time, and that was making … boot scrapers! I had an order to complete, and then I wire-brushed five of the seven that David had needled. I gave up at that point and saved the last two for next time … and yet … David was now painting the bottoms

of these five with black paint! How does he do it?

Roger

Unable to needle-gun rail chairs on Saturday due to rain, so had to pop down for an hour to clean two orders. Tripped the electricity in the box - don’t know why. Key to the power distribution board was not where it should have been, so I pulled out another plug and used that socket. Drill with wire brush attachment went on strike - loose or broken cable. No time to repair, so dumped it on the workbench and used another … At least these two chairs now have black bottoms.

Wednesday 14th

John G began by applying primer coat to the two rail chairs. I joined him in the container to paint the lettering on the chairs in the production line. John Mayell snook in, pinched the one black boot scraper and ran off with it. John G wrestled him to the ground and extracted the money for it.

Last week, John G had refitted the ferrules around the inspection plugs in the cab … except that (allegedly) Gilbert had lost one of the fixing bolts. John found one to fit and hence completed that task. As Head Painter, John was then tasked with slapping some black on those fitted bolt heads that David & John T completed last week. Thereafter, John G began to polish the brasswork in the cab, but ran out of polish and time.

During the removal of the spring compensating beam last week, Bruce had discovered that the piece of angle bracket to which a chain is attached (yellow arrow, left) was loose - though the nut was seized solid. The chain, by the way, is purely a safety measure: if the brake stretcher should break free (e.g. the nut fall of its end) the chain prevents the stretcher from fouling the rail/wheel/track.

Bruce struggled to find a spanner to fit the “standard” ¾” Whitworth nut; I think he filed the nut down to fit the spanner in the end (though he denied that that’s what he was doing … with the nut in the vice and the file in his hand …).

Gilbert went round spreading grease everywhere. Since this grease is coloured red, it’s a tad hard to disguise (see red arrows in photo).

Gil’s convinced that grease would not go into the nipples on the other three compensating beam pivots. I guess these will have to come off to see if these pivot pins have seized in their beams, too! A job for Winter Maintenance.

Saturday 17th

For his homework, David is making a gadget for measuring the valve timing. He brought the first

part in today to check the alignment of the holes. The first thing he discovered was that the studs

are not necessarily in exactly the same positions on different 28xx locos! So, he had to make the

holes a bit bigger.

The angle sits on three studs in the front of the valve chest (yellow arrows, right). This is just the first part. There will follow pieces that allow the movement of the valve rod to be monitored and marked. We will be able to determine what movement there is relative to the centre point, and hence if the valve is too far forwards or back. If it is, then steam will be let in (and also out) of the valve at lightly less than the optimum time.

I’ll keep you posted as more bits of the gadget are made.

After checking this, David played with our compressor for a while (neither of us spotting that the exhaust valve was wide open - which kind of limited the pressure that the compressor was able to build up!). Once up & running, David made up for lost time by needle-gunning seven rail chairs.

Meanwhile, Gilbert had been poring over diagrams (as is his wont), finally deciding that he would check the play in all of the coupling and connecting rods.

David (as if he had some fantastic control over the space-time over the continuum) also assisted Gil in taking some of those measurements.

I, on the other hand, could only be in one place at a time, and that was making … boot scrapers! I had an order to complete, and then I wire-brushed five of the seven that David had needled. I gave up at that point and saved the last two for next time … and yet … David was now painting the bottoms

of these five with black paint! How does he do it?

Roger

Sunday, 11 December 2016

Maintenance Update (hanger, jack, bolt, eccentric)

Wednesday 7th

Bruce reports:

“Wednesday started by getting 2807 over the pit with coupling rods in the correct position to give better access to the brake hanger and spring compensator.

It’s difficult to give a progressive account as we were all doing different things at the same time.

Bruce concentrated on the large pin, freeing the large nut and then reamed out the split pin holes, he then re tapped the grease nipple thread and fitted the grease nipple.

Gilbert and Brian, assisted by Alex and Pete (loco dept) jacked up the loco and removed the spring hanger links followed by the spring compensating beam.

All these parts were cleaned and refurbished, including re-cutting threads where required.

The parts were then assembled, including the new spring hanger link, and the springs adjusted, the nuts were tightened about the same as those on the other springs. Some of the brake linkages had been removed on Saturday to give better access so these were reassembled and new split pins inserted.

The jacks were removed and the loco was inspected by John P and declared serviceable.

The weights will need to be checked later when we can get access to the weighbridge.

John G painted some more rail chairs and then took the opportunity to paint the visible side of the linkages on the loco while they were clean, as the paint had been burnt off when it was heated to remove the pin.

We all seemed to have our fingers in the pie at some point, including members of the loco department but in particular Alex and Pete, so, thanks to all.

Just before tea break in the morning Roger called in to collect a few bits and pieces so, as we all had our tongues hanging out Bruce went and made the tea, including one for Roger, unfortunately he did not appear so Brian, hating the idea of waste, polished off Roger's as well, including the cake that Bruce had brought in to celebrate his birthday.”

Yes, sorry chaps! Wednesday was manic for me: I only just had time to pop down (between the Tesco run and taking Mum for her cataract operation) and pick up an LMS boot scraper for an order. Boot scraper parcelled and sent to Ayrshire by UK Mail on Thursday; arrived Saturday.

Happy birthday, Bruce!

Saturday 10th

David and John T decided to have a go at the remaining two fitted bolts on the LHS rocking shaft bracket. David spent the day between the frames reaming out the holes, while John was on the outside, catching the reamer, cleaning it, expanding it and lubricating it again before passing it back to David.

The fitted bolts have to be such a tight fit that they need quite some persuasion to go into their holes!

It did take all day, and both Bruce and Roger lent a hand at times. But by end of play, both bolts were fitted.

While he’d got used to being stuck inside there, David had a look at the eccentric sleeves, as there had been a report of looseness in them. One was found to have sideways play, but no front-to-back play (which would be more concerning). So, we won’t take any action on that at present.

Bruce tackled one of the logged issues that said that the heating valve to the hydrostatic lubricator was leaking.

Aided and assisted by Gil, he removed the valve and began lapping it in. However, the seat was a bit rough, and the angles of the surfaces do need to be the same in order to seal! So, Bruce made a gadget with the correct angled point which fitted snugly into the valve such that it was able to cut the seat true.

I was preoccupied selling, restocking and painting more boot scrapers.

Roger

Bruce reports:

“Wednesday started by getting 2807 over the pit with coupling rods in the correct position to give better access to the brake hanger and spring compensator.

It’s difficult to give a progressive account as we were all doing different things at the same time.

Bruce concentrated on the large pin, freeing the large nut and then reamed out the split pin holes, he then re tapped the grease nipple thread and fitted the grease nipple.

Gilbert and Brian, assisted by Alex and Pete (loco dept) jacked up the loco and removed the spring hanger links followed by the spring compensating beam.

All these parts were cleaned and refurbished, including re-cutting threads where required.

The parts were then assembled, including the new spring hanger link, and the springs adjusted, the nuts were tightened about the same as those on the other springs. Some of the brake linkages had been removed on Saturday to give better access so these were reassembled and new split pins inserted.

The jacks were removed and the loco was inspected by John P and declared serviceable.

The weights will need to be checked later when we can get access to the weighbridge.

John G painted some more rail chairs and then took the opportunity to paint the visible side of the linkages on the loco while they were clean, as the paint had been burnt off when it was heated to remove the pin.

We all seemed to have our fingers in the pie at some point, including members of the loco department but in particular Alex and Pete, so, thanks to all.

Just before tea break in the morning Roger called in to collect a few bits and pieces so, as we all had our tongues hanging out Bruce went and made the tea, including one for Roger, unfortunately he did not appear so Brian, hating the idea of waste, polished off Roger's as well, including the cake that Bruce had brought in to celebrate his birthday.”

Yes, sorry chaps! Wednesday was manic for me: I only just had time to pop down (between the Tesco run and taking Mum for her cataract operation) and pick up an LMS boot scraper for an order. Boot scraper parcelled and sent to Ayrshire by UK Mail on Thursday; arrived Saturday.

Happy birthday, Bruce!

Saturday 10th

David and John T decided to have a go at the remaining two fitted bolts on the LHS rocking shaft bracket. David spent the day between the frames reaming out the holes, while John was on the outside, catching the reamer, cleaning it, expanding it and lubricating it again before passing it back to David.

The fitted bolts have to be such a tight fit that they need quite some persuasion to go into their holes!

It did take all day, and both Bruce and Roger lent a hand at times. But by end of play, both bolts were fitted.

While he’d got used to being stuck inside there, David had a look at the eccentric sleeves, as there had been a report of looseness in them. One was found to have sideways play, but no front-to-back play (which would be more concerning). So, we won’t take any action on that at present.

Bruce tackled one of the logged issues that said that the heating valve to the hydrostatic lubricator was leaking.

Aided and assisted by Gil, he removed the valve and began lapping it in. However, the seat was a bit rough, and the angles of the surfaces do need to be the same in order to seal! So, Bruce made a gadget with the correct angled point which fitted snugly into the valve such that it was able to cut the seat true.

I was preoccupied selling, restocking and painting more boot scrapers.

Roger

Saturday, 3 December 2016

Maintenance Update (test, beam, arch, grease)

Sunday 27th

Brian drove over from Sunbury on Thames to help light warming fires. Silly boy asked Carpo if he needed help on Monday too: “Brian, The warming fires (2807 and 7820) are now in and Clive Norton is due in tomorrow morning at 7. Please assist him as required.”

Carpo also commented on the bent spring hanger: “From a mechanical point of view the engine is a fail until such time as this is replaced … It is now too weak for purpose and will have to be replaced.”

Monday 28th

Carpo reported: “I'm pleased to be able report that 2807 passed her steam test today with no issues as far the boiler was concerned. My thanks to Clive Norton and Brian who looked after the fire and made sure that she was ready for inspection despite the late arrival of the boiler inspector.”

We have a spare hanger that could be fitted on Wednesday. Gil has requested we are put over a pit this coming Wednesday to look at the issue with the spring hanger link. However, methinks there’s little point in replacing it if we have not identified and fixed the fault.

As a reward for their dedication, Gil & Brian went for a gentle run up and down road one for 20mins.

Wednesday 30th

Lots of help from the Loco Dept chaps today. Several of them were shovelling coal out of our tender and into the JCB bucket. This coal creates such a black smoke that the Dept decided to mix it in with our normal coal to minimise its effect. Anyone who has any doubts about this dreadfully filthy coal should take a look at the photo on page 42 of the December Steam Railway magazine! I’m sure that it would take too long to track down Phil Metcalfe and obtain his permission to reproduce his photo, so you’ll have to use your imagination!

Bruce verified that the rear compensating beam is ¾” longer on one side than the other ... and that we fitted it the wrong way round! The RHS one is OK (I guess it was a 50-50 chance anyway if we didn’t realise the beams were asymmetric). Bruce also calculated the effect of ¾” in the wrong direction, and it works out at approx. 0.4 ton weight on the wheel. This explains an anomaly that Gil had with the weights. The RHS trailing and driving wheels were equal weights, but the LHS ones differ by 0.9 ton! Now we know why. So, Bruce, Gil, Brian plus Carpo and John The Flame [Loco Dept] spent all day trying to disassemble the two spring hangers and the beam. Much flame throwing ensued:

At one point, the oil on the insulation around the steam heating pipe caught fire and Bruce had to man the hose. Mostly, though, the nuts on the hangers and the beam’s pivot pin were objecting strongly to being removed.

By end of play the nuts were all (relatively) loose, but the pivot pin through the compensating beam was firmly seized within the beam. Much heating and bashing failed to budge it. So, the loco was gently rolled back into the shed and we shall try again on Saturday.

Numerous Loco Dept chaps (and chapess Alex) cleaned out the ash from the grate and the ash pan. Clive then began to assemble the brick arch. Inevitably the bricks do not quite fit together and the keystone needs a shade slicing off each of the sides. Again, it was late in the day and completion of this task is another Saturday job.

Meanwhile, John G and I almost froze to death inside the container progressing boot scrapers. There was frost on the rail chairs in there (which didn’t help with the painting). We never managed to get the place warm. Nevertheless, John painted five bottoms plus many brushes; I completed the lettering on the 11 in the production line.

Saturday 3rd

The first thing that I did was to fit a new halogen heater bar in the fire in the container, replacing a bar that had died! Double the heat makes a dramatic difference!

Apart from me finishing off some boot scrapers and restocking the F&W, everyone tackled the obstinate compensating beam pin: Gil, Bruce, John T and Carpo.

In fairness, there was also a team of Loco Dept chaps, under the guidance of Clive, continuing with fitting the brick arch. By end of play, this was complete. The keystones all seemed to have to be adjusted (using a diamond cutting disc). Our thanks go to all of these chaps.

Note the pristine condition! You may also just see the ends of the metal rods that run along each side of the firebox (resting on pins as explained a couple of weeks ago) and you can see how these rods provide support for the bricks at the sides.

Back to the compensating beam:

Much heating and bashing ensued, made difficult by parts of the brake rigging getting in the way. Ditto the ash pan, but that’s a shade harder to remove! So, not only was the brake shoe and hanger taken off, but the stretcher between the hangers on this and the other side; and the actuation rods that fit onto the stretcher were all removed. Finally, you could get a good swing at the pin (though the ash pan took a hit from time to time, too!).

Believe it or not, it was mid-afternoon before the blighter moved! Bruce was chief flame thrower; Gil & I took turns with the mallet from within the pit; John T used the lump hammer outside the pit. Once we had persuaded the pin to move outwards, Andy [P&O] suggested knocking it back in, and then out/in, out/in, to try to free the rust that was gripping it. This worked, and finally the pin flew out in John’s direction.

Gil decided that was enough for today, so he, John & I reassembled the brake rigging to enable the loco to be pushed back into the shed.

Bruce took the pin into the workshop and tidied it up. The thread had taken some damage through having its end bashed for two days; the centre (where it had jammed) had a couple of thou shaved off; and then Bruce decided to cut a shallow channel round the centre to enable grease to flow more easily onto and around the pin. It is likely that grease has blocked the existing hole and been unable to reach the pin - hence it jamming.

On Wednesday we shall remove the beam; clean it up, turn it round and refit it. We shall replace the bent hanger, and all will be hunky dory!

Roger

Brian drove over from Sunbury on Thames to help light warming fires. Silly boy asked Carpo if he needed help on Monday too: “Brian, The warming fires (2807 and 7820) are now in and Clive Norton is due in tomorrow morning at 7. Please assist him as required.”

Carpo also commented on the bent spring hanger: “From a mechanical point of view the engine is a fail until such time as this is replaced … It is now too weak for purpose and will have to be replaced.”

Monday 28th

Carpo reported: “I'm pleased to be able report that 2807 passed her steam test today with no issues as far the boiler was concerned. My thanks to Clive Norton and Brian who looked after the fire and made sure that she was ready for inspection despite the late arrival of the boiler inspector.”

We have a spare hanger that could be fitted on Wednesday. Gil has requested we are put over a pit this coming Wednesday to look at the issue with the spring hanger link. However, methinks there’s little point in replacing it if we have not identified and fixed the fault.

As a reward for their dedication, Gil & Brian went for a gentle run up and down road one for 20mins.

Wednesday 30th

Lots of help from the Loco Dept chaps today. Several of them were shovelling coal out of our tender and into the JCB bucket. This coal creates such a black smoke that the Dept decided to mix it in with our normal coal to minimise its effect. Anyone who has any doubts about this dreadfully filthy coal should take a look at the photo on page 42 of the December Steam Railway magazine! I’m sure that it would take too long to track down Phil Metcalfe and obtain his permission to reproduce his photo, so you’ll have to use your imagination!

Bruce verified that the rear compensating beam is ¾” longer on one side than the other ... and that we fitted it the wrong way round! The RHS one is OK (I guess it was a 50-50 chance anyway if we didn’t realise the beams were asymmetric). Bruce also calculated the effect of ¾” in the wrong direction, and it works out at approx. 0.4 ton weight on the wheel. This explains an anomaly that Gil had with the weights. The RHS trailing and driving wheels were equal weights, but the LHS ones differ by 0.9 ton! Now we know why. So, Bruce, Gil, Brian plus Carpo and John The Flame [Loco Dept] spent all day trying to disassemble the two spring hangers and the beam. Much flame throwing ensued:

At one point, the oil on the insulation around the steam heating pipe caught fire and Bruce had to man the hose. Mostly, though, the nuts on the hangers and the beam’s pivot pin were objecting strongly to being removed.

By end of play the nuts were all (relatively) loose, but the pivot pin through the compensating beam was firmly seized within the beam. Much heating and bashing failed to budge it. So, the loco was gently rolled back into the shed and we shall try again on Saturday.

Numerous Loco Dept chaps (and chapess Alex) cleaned out the ash from the grate and the ash pan. Clive then began to assemble the brick arch. Inevitably the bricks do not quite fit together and the keystone needs a shade slicing off each of the sides. Again, it was late in the day and completion of this task is another Saturday job.

Meanwhile, John G and I almost froze to death inside the container progressing boot scrapers. There was frost on the rail chairs in there (which didn’t help with the painting). We never managed to get the place warm. Nevertheless, John painted five bottoms plus many brushes; I completed the lettering on the 11 in the production line.

Saturday 3rd

The first thing that I did was to fit a new halogen heater bar in the fire in the container, replacing a bar that had died! Double the heat makes a dramatic difference!

Apart from me finishing off some boot scrapers and restocking the F&W, everyone tackled the obstinate compensating beam pin: Gil, Bruce, John T and Carpo.

In fairness, there was also a team of Loco Dept chaps, under the guidance of Clive, continuing with fitting the brick arch. By end of play, this was complete. The keystones all seemed to have to be adjusted (using a diamond cutting disc). Our thanks go to all of these chaps.

Note the pristine condition! You may also just see the ends of the metal rods that run along each side of the firebox (resting on pins as explained a couple of weeks ago) and you can see how these rods provide support for the bricks at the sides.

Back to the compensating beam:

Much heating and bashing ensued, made difficult by parts of the brake rigging getting in the way. Ditto the ash pan, but that’s a shade harder to remove! So, not only was the brake shoe and hanger taken off, but the stretcher between the hangers on this and the other side; and the actuation rods that fit onto the stretcher were all removed. Finally, you could get a good swing at the pin (though the ash pan took a hit from time to time, too!).

Believe it or not, it was mid-afternoon before the blighter moved! Bruce was chief flame thrower; Gil & I took turns with the mallet from within the pit; John T used the lump hammer outside the pit. Once we had persuaded the pin to move outwards, Andy [P&O] suggested knocking it back in, and then out/in, out/in, to try to free the rust that was gripping it. This worked, and finally the pin flew out in John’s direction.

Gil decided that was enough for today, so he, John & I reassembled the brake rigging to enable the loco to be pushed back into the shed.

Bruce took the pin into the workshop and tidied it up. The thread had taken some damage through having its end bashed for two days; the centre (where it had jammed) had a couple of thou shaved off; and then Bruce decided to cut a shallow channel round the centre to enable grease to flow more easily onto and around the pin. It is likely that grease has blocked the existing hole and been unable to reach the pin - hence it jamming.

On Wednesday we shall remove the beam; clean it up, turn it round and refit it. We shall replace the bent hanger, and all will be hunky dory!

Roger

Sunday, 27 November 2016

Maintenance Update (bone, brass, rock, homework)

Sunday 20th

Carpo “boxed up” the loco (i.e. fitted remaining mud hole doors and inserted all of the washout plugs) and lit a small warming fire: “If all is well tomorrow morning then I shall relight and we shall bring it round slowly”.

Monday 21st

Remember Monday? That was the day that it rained!

I arrived at 9 o’clock as Carpo was making his breakfast. He was happy for me to light the fire, so I went and got changed. On my way to the van, I turned on the water for a cuppa, but when I got to the van, there was water gushing out of the pipe. It looked as though the (hose) pipe had “exploded”, about 8 inches from the tap. “Curious”, I thought. Once inside, I turned on the radiator - no electricity! It took me a while to put two and two together, but it appears that the diesel guys had been shunting on Sunday, and it seemed that they had given “our” van a bit of a bash! That’s what had torn our water supply in half; but also it ripped our mains cable out of its socket; in fact there was no sign of the plug at all (perhaps someone picked it up). So, amid bouts of shovelling coal, I also fixed our water supply; found another blue plug, re-routed our mains cable and fitted the plug. Nevertheless, it was twenty to twelve before I got my elevenses!

The firebox was dry as a bone, so I lit a fire as if it were a warming fire - just on the level, rear part of the grate. Once that was well established, I raked it forward and spread more coal around. Gradually this covered the whole grate area, and it was just a matter of time. This coal (left over from 2807’s trip to Yorkshire) is filthy stuff! The smoke was appallingly black. I wish I’d taken my camera …

As pressure slowly crept up, Carpo kept popping back to check on things. The blow-down valve needed tightening; the gauge frame nuts needed tightening (by hand only); a couple of mud hole doors were leaking steam, and the tender had no water in it. I abandoned ship at 2 pm, by which time there was 120 psi “on the clock”.

Carpo later reported: “so far the steam test has been successful with a high 180lb achieved this afternoon. I would have taken the pressure higher but I need to adjust the safety valves to do this and I didn't fancy doing that this afternoon whilst it was blowing a hoolie!”

Tuesday 22nd

Carpo reported: “You will be pleased to know that 219lb was reached today without any leakage from the replaced tube evident. I would like to check this once she has cooled down but it would appear that we are ready for the inspector next Monday.”

Wednesday 23rd

Following on from the water & electrics fiasco on Monday, it became clear when examining the rails, that “our” van had been shunted at least 20 feet along the track. Presumably, whoever did this had not realised that several vehicles were coupled together? Whether or not, they neglected to check that any of these vehicles was connected to a power supply! The finger points at the Class 26 & 45 group, as their locos are at the head of the line!

Pressure was off (literally) and today felt like it. The hardest working person today was John G, who applied a primer coat to eleven rail chairs! Is this a record?

Bruce checked that the safety valves had been tightened onto the spacers, and then fitted the brass bonnet.

We had three visitors who wanted to take a look at 2807. We’re always pleased to have our supporters pop in for a look and a chat.

I checked the state of the new tube and there was no sign of any leaking from front or back; then I removed the pressure gauge to enable it to be calibrated before the inspector comes on Monday.

Chris [Loco Dept] clambered into the firebox to clear out the ash.

Large chunks of what looks like rock were in the midst of the ash!

Mike [Loco dept] assisted Chris in finally disposing the engine, and Bruce helped by shovelling the ash out of the pit into their barrows.

Gilbert, Brian & Steve had a meeting to progress the plan for the Heavy General Overhaul. At best, we have three years left to run before the inevitable is upon us.

While he was underneath the loco, Bruce spotted a bit of a whoopsie. Our loco is unusual in that the wheels are not entirely independently sprung. Some adjacent pairs of springs are connected by a compensating beam. The purpose is not clear, though it may make the ride smoother over rough track. Well, Bruce spotted that one of the suspension links from spring to beam is a tad bent!

Bruce’s current thought is that the beam is not symmetrical, and we may have fitted it the wrong way round. This end is too long, and hence has pushed & bent the link. Further investigation is required!

Saturday 26th

Bruce brought his homework in to show us. He has made two parts to fit in the ends of the hose that serves as a boiler tube cleaner. One end has “teeth” to gnaw away at any blockages; the other is made to fit onto our hoover hose. This makes it a heck of a lot easier to access the boiler tubes from within the firebox (and even from within the smokebox) to suck (or blow) ash out of the tubes.

John T volunteered to clean more rail chairs. Meanwhile, I slapped an enamel top coat onto those in the production line.

I suddenly remembered the bright red rail chair that we made for the GWSR. This is used at Winchcombe station to show the driver where to stop. It is adapted to take a sign which reads: “Santa stop here”. I’ll drop that down to Winchcombe next week.

The station shop has taken over the last remnants of our bespoke Dapol 00 scale wagons. These were all models of actual wagons from local coal merchants.

Bruce and Gilbert tackled yet another (the second of four) fitted bolt on the LHS rock shaft. This is one of those tasks that slowly moves forward when there’s nothing else to do!

The RHS rock shaft has all four fitted bolts now. The shank of the bolt fits so tightly into the hole that it has to be hammered home. The bolt is inserted from the outside of the frames. In order to be able to hit the bolt head, when various bits of frame get in the way, we have made a special tool. This holds the (yellow) rod in place on the bolt head while the bar is being whacked, thus:-

Bruce points out that it took almost as long to gather together the correct set of tools (especially finding the correct size of expanding reamer; and then the right size spanner to adjust the expansion) as to ream the hole!

Other than that, I put a top coat on the beading around the front edge of the cab, where we had cleaned off rust and tidied it up.

Formal steam test on Monday !!! Warming fire needed on Sunday.

Roger

Carpo “boxed up” the loco (i.e. fitted remaining mud hole doors and inserted all of the washout plugs) and lit a small warming fire: “If all is well tomorrow morning then I shall relight and we shall bring it round slowly”.

Monday 21st

Remember Monday? That was the day that it rained!

I arrived at 9 o’clock as Carpo was making his breakfast. He was happy for me to light the fire, so I went and got changed. On my way to the van, I turned on the water for a cuppa, but when I got to the van, there was water gushing out of the pipe. It looked as though the (hose) pipe had “exploded”, about 8 inches from the tap. “Curious”, I thought. Once inside, I turned on the radiator - no electricity! It took me a while to put two and two together, but it appears that the diesel guys had been shunting on Sunday, and it seemed that they had given “our” van a bit of a bash! That’s what had torn our water supply in half; but also it ripped our mains cable out of its socket; in fact there was no sign of the plug at all (perhaps someone picked it up). So, amid bouts of shovelling coal, I also fixed our water supply; found another blue plug, re-routed our mains cable and fitted the plug. Nevertheless, it was twenty to twelve before I got my elevenses!

The firebox was dry as a bone, so I lit a fire as if it were a warming fire - just on the level, rear part of the grate. Once that was well established, I raked it forward and spread more coal around. Gradually this covered the whole grate area, and it was just a matter of time. This coal (left over from 2807’s trip to Yorkshire) is filthy stuff! The smoke was appallingly black. I wish I’d taken my camera …

As pressure slowly crept up, Carpo kept popping back to check on things. The blow-down valve needed tightening; the gauge frame nuts needed tightening (by hand only); a couple of mud hole doors were leaking steam, and the tender had no water in it. I abandoned ship at 2 pm, by which time there was 120 psi “on the clock”.

Carpo later reported: “so far the steam test has been successful with a high 180lb achieved this afternoon. I would have taken the pressure higher but I need to adjust the safety valves to do this and I didn't fancy doing that this afternoon whilst it was blowing a hoolie!”

Tuesday 22nd

Carpo reported: “You will be pleased to know that 219lb was reached today without any leakage from the replaced tube evident. I would like to check this once she has cooled down but it would appear that we are ready for the inspector next Monday.”

Wednesday 23rd

Following on from the water & electrics fiasco on Monday, it became clear when examining the rails, that “our” van had been shunted at least 20 feet along the track. Presumably, whoever did this had not realised that several vehicles were coupled together? Whether or not, they neglected to check that any of these vehicles was connected to a power supply! The finger points at the Class 26 & 45 group, as their locos are at the head of the line!

Pressure was off (literally) and today felt like it. The hardest working person today was John G, who applied a primer coat to eleven rail chairs! Is this a record?

Bruce checked that the safety valves had been tightened onto the spacers, and then fitted the brass bonnet.

We had three visitors who wanted to take a look at 2807. We’re always pleased to have our supporters pop in for a look and a chat.

I checked the state of the new tube and there was no sign of any leaking from front or back; then I removed the pressure gauge to enable it to be calibrated before the inspector comes on Monday.

Chris [Loco Dept] clambered into the firebox to clear out the ash.

Large chunks of what looks like rock were in the midst of the ash!

Mike [Loco dept] assisted Chris in finally disposing the engine, and Bruce helped by shovelling the ash out of the pit into their barrows.

Gilbert, Brian & Steve had a meeting to progress the plan for the Heavy General Overhaul. At best, we have three years left to run before the inevitable is upon us.

While he was underneath the loco, Bruce spotted a bit of a whoopsie. Our loco is unusual in that the wheels are not entirely independently sprung. Some adjacent pairs of springs are connected by a compensating beam. The purpose is not clear, though it may make the ride smoother over rough track. Well, Bruce spotted that one of the suspension links from spring to beam is a tad bent!

Bruce’s current thought is that the beam is not symmetrical, and we may have fitted it the wrong way round. This end is too long, and hence has pushed & bent the link. Further investigation is required!

Saturday 26th

Bruce brought his homework in to show us. He has made two parts to fit in the ends of the hose that serves as a boiler tube cleaner. One end has “teeth” to gnaw away at any blockages; the other is made to fit onto our hoover hose. This makes it a heck of a lot easier to access the boiler tubes from within the firebox (and even from within the smokebox) to suck (or blow) ash out of the tubes.

John T volunteered to clean more rail chairs. Meanwhile, I slapped an enamel top coat onto those in the production line.

I suddenly remembered the bright red rail chair that we made for the GWSR. This is used at Winchcombe station to show the driver where to stop. It is adapted to take a sign which reads: “Santa stop here”. I’ll drop that down to Winchcombe next week.

The station shop has taken over the last remnants of our bespoke Dapol 00 scale wagons. These were all models of actual wagons from local coal merchants.

Bruce and Gilbert tackled yet another (the second of four) fitted bolt on the LHS rock shaft. This is one of those tasks that slowly moves forward when there’s nothing else to do!

The RHS rock shaft has all four fitted bolts now. The shank of the bolt fits so tightly into the hole that it has to be hammered home. The bolt is inserted from the outside of the frames. In order to be able to hit the bolt head, when various bits of frame get in the way, we have made a special tool. This holds the (yellow) rod in place on the bolt head while the bar is being whacked, thus:-

Bruce points out that it took almost as long to gather together the correct set of tools (especially finding the correct size of expanding reamer; and then the right size spanner to adjust the expansion) as to ream the hole!

Other than that, I put a top coat on the beading around the front edge of the cab, where we had cleaned off rust and tidied it up.

Formal steam test on Monday !!! Warming fire needed on Sunday.

Roger

Sunday, 20 November 2016

Maintenance Update (plugs, arch, timing, fire)

Saturday 12th

... was cancelled! However, I took Rowan, my 2-yr old grandson, to Toddington because he loves the trains, and there happened to be a race train this day. I don’t think he was greatly impressed by the loco being black instead of green! He was impressed with the yard shunting, though - buffering up and coupling, plus the diesel shunter then pootling off down the line on its own; and seeing a fork lift truck in action (they are usually sat idle when he sees them). It was a hive of activity - which was great for Rowan.

Of course, there is always a danger that I will get sucked into something when I turn up “off duty”, and today was no exception: the railway had decided to move ex-our TPO, so they also needed the keys to our paint store … which are kept inside the van that we are using!

Wednesday 16th

Today was the day to wash out the boiler. Brian and Gil removed the last two wash-out plugs from within the smokebox, while everything was got ready. John G was in the container, cleaning the old gaskets off the mud hole doors and shining them up a little.

That took care of our remaining two wire brushes! Gil set up the electric version outside, and began cleaning the threads on the wash out plugs.

After lunch the action began for real! Brian was persuaded to clamber onto the loco and insert the hose into each orifice in turn. John G manned the pump and Bruce controlled the tap.

I was inside the container, when there was a sudden downpour! The chaps made a run for it; Brian (who was by now at the chimney end) yelled for someone to hold the ladder (but no one could hear because of the rain!!!); Gil, who was still wire-brushing outside, dived under the platform that used to lead up to the TPO (but now leads nowhere).

Well, if they weren’t wet from the washing out, they were certainly wet now!

After the storm and the washing out, Carpo, Brian and John formed a chain passing fire bars up and into the firebox. The grate is now in place. Four of the (cleaned) mud hole doors had been refitted, and the other four had gaskets fitted in readiness. Still firing on all two cylinders, the intrepid trio proceeded to gather up the superheater tubes and feed these into the smokebox and down their flues. There was no time to fit them, but at least they are in the right place.

Bruce cleaned up the components of the gauge frame ready for that to be refitted on Saturday. The current (!) plan is to complete everything on Saturday and light a warming fire, followed by an informal steam test on Sunday or Monday.

The brick arch is not yet in place, but two bars have been delivered. These run along each side of the firebox, sitting on five studs, and form a foundation for the bricks of the arch. They need bending to fit the contour of the firebox sides. The fusible plugs have not been changed, either, so there are still a few things to do. The formal steam test is scheduled for 28th, I believe.

Saturday 19th

Here you can see the contour of the firebox side, and how the five studs are spread across the curve.

And here is David test fitting a bar and working out where to apply a bend.

Gilbert is in there, too, but is hiding behind David! By end of play, both bars had been cut to length and bent to fit the sides. They are ready to take the brick arch, but this will not be fitted until after a steam test.

It was a tad cool outside (actually, it was even cooler inside the loco shed!), but John T insisted on cleaning up more rail chairs for us. In doing so, he stumbled upon one with his very own birth date upon it! So, that one is now reserved. Meanwhile, a lady from north of the border has ordered an LMS boot scraper, so John tackled that to start with. I have discovered that boot scrapers are just inside the weight limit accepted by UK Mail, so we can now despatch them country-wide.

Last week I sent one to Kent. In fact, at 09.30 this morning I was handing over a 1946 special order to a couple from Swindon - it’s her father’s year of birth, of course.

Back to Gil & David: they are working on making a gadget to enable the timing of the cylinder valves to be adjusted. It’s nice to get a near-perfect beat. Ours was alright until we inserted fitted bolts into the RHS rock shaft. This stopped it from rocking in the wrong direction, but until then its unintended movement was compensated by the valve setting, resulting in a regular beat … Now it doesn’t budge, we’ve got to adjust the valve!

Bruce seized the chance to sit on top of the boiler once again:

He lapped the steam safety valves (though they barely needed doing, having lasted extremely well since he last did them ages ago). That took Bruce most of the day. Note the comfort blanket under his bottom - there’s a noticeable difference in temperature when the loco is not in steam. 🙂

I pressed on with the leading edges of the cab, which had been filled last week. I sanded this down and applied a primer coat. I don’t expect the top coat to quite match the 10-yr old paint on the rest of the cab, but I’ll do my best.

Finally, I fitted the gauge frame in the cab. So, the remaining holes in the boiler are: four mud hole doors plus a box full of wash-out plugs. Carpo says: “I will however do this [box up] on Sunday (or at least get the bulk of it done) so that I can try and put in a warming fire and steam test on Monday.” He added: “I think the fusible plugs have only done 15 or so steamings so they can stay in for the Santa Specials and we will remove in Jan.”

Roger

... was cancelled! However, I took Rowan, my 2-yr old grandson, to Toddington because he loves the trains, and there happened to be a race train this day. I don’t think he was greatly impressed by the loco being black instead of green! He was impressed with the yard shunting, though - buffering up and coupling, plus the diesel shunter then pootling off down the line on its own; and seeing a fork lift truck in action (they are usually sat idle when he sees them). It was a hive of activity - which was great for Rowan.

Of course, there is always a danger that I will get sucked into something when I turn up “off duty”, and today was no exception: the railway had decided to move ex-our TPO, so they also needed the keys to our paint store … which are kept inside the van that we are using!

Wednesday 16th

Today was the day to wash out the boiler. Brian and Gil removed the last two wash-out plugs from within the smokebox, while everything was got ready. John G was in the container, cleaning the old gaskets off the mud hole doors and shining them up a little.

That took care of our remaining two wire brushes! Gil set up the electric version outside, and began cleaning the threads on the wash out plugs.

After lunch the action began for real! Brian was persuaded to clamber onto the loco and insert the hose into each orifice in turn. John G manned the pump and Bruce controlled the tap.

I was inside the container, when there was a sudden downpour! The chaps made a run for it; Brian (who was by now at the chimney end) yelled for someone to hold the ladder (but no one could hear because of the rain!!!); Gil, who was still wire-brushing outside, dived under the platform that used to lead up to the TPO (but now leads nowhere).

Well, if they weren’t wet from the washing out, they were certainly wet now!

After the storm and the washing out, Carpo, Brian and John formed a chain passing fire bars up and into the firebox. The grate is now in place. Four of the (cleaned) mud hole doors had been refitted, and the other four had gaskets fitted in readiness. Still firing on all two cylinders, the intrepid trio proceeded to gather up the superheater tubes and feed these into the smokebox and down their flues. There was no time to fit them, but at least they are in the right place.

Bruce cleaned up the components of the gauge frame ready for that to be refitted on Saturday. The current (!) plan is to complete everything on Saturday and light a warming fire, followed by an informal steam test on Sunday or Monday.

The brick arch is not yet in place, but two bars have been delivered. These run along each side of the firebox, sitting on five studs, and form a foundation for the bricks of the arch. They need bending to fit the contour of the firebox sides. The fusible plugs have not been changed, either, so there are still a few things to do. The formal steam test is scheduled for 28th, I believe.

Saturday 19th

Here you can see the contour of the firebox side, and how the five studs are spread across the curve.

And here is David test fitting a bar and working out where to apply a bend.

Gilbert is in there, too, but is hiding behind David! By end of play, both bars had been cut to length and bent to fit the sides. They are ready to take the brick arch, but this will not be fitted until after a steam test.

It was a tad cool outside (actually, it was even cooler inside the loco shed!), but John T insisted on cleaning up more rail chairs for us. In doing so, he stumbled upon one with his very own birth date upon it! So, that one is now reserved. Meanwhile, a lady from north of the border has ordered an LMS boot scraper, so John tackled that to start with. I have discovered that boot scrapers are just inside the weight limit accepted by UK Mail, so we can now despatch them country-wide.

Last week I sent one to Kent. In fact, at 09.30 this morning I was handing over a 1946 special order to a couple from Swindon - it’s her father’s year of birth, of course.

Back to Gil & David: they are working on making a gadget to enable the timing of the cylinder valves to be adjusted. It’s nice to get a near-perfect beat. Ours was alright until we inserted fitted bolts into the RHS rock shaft. This stopped it from rocking in the wrong direction, but until then its unintended movement was compensated by the valve setting, resulting in a regular beat … Now it doesn’t budge, we’ve got to adjust the valve!

Bruce seized the chance to sit on top of the boiler once again:

He lapped the steam safety valves (though they barely needed doing, having lasted extremely well since he last did them ages ago). That took Bruce most of the day. Note the comfort blanket under his bottom - there’s a noticeable difference in temperature when the loco is not in steam. 🙂

I pressed on with the leading edges of the cab, which had been filled last week. I sanded this down and applied a primer coat. I don’t expect the top coat to quite match the 10-yr old paint on the rest of the cab, but I’ll do my best.

Finally, I fitted the gauge frame in the cab. So, the remaining holes in the boiler are: four mud hole doors plus a box full of wash-out plugs. Carpo says: “I will however do this [box up] on Sunday (or at least get the bulk of it done) so that I can try and put in a warming fire and steam test on Monday.” He added: “I think the fusible plugs have only done 15 or so steamings so they can stay in for the Santa Specials and we will remove in Jan.”

Roger

Thursday, 10 November 2016

Maintenance Update (slug, wall, annealed, swaged)

Monday 7th

Gil, Bruce and I joined Carpo with a view to finishing off making the new boiler tube. When we looked at the end that we had opened out on Saturday, we decided that it was good, but it wasn’t Carling. So, we cut it off and started again!

This time, Carpo heated a narrower area of tube before we hit it, thus avoiding any deformation above the bit we were trying to open out. Also, we did the hitting on the horizontal, which gave us much better control over the angle of the pipe (90°) against the immovable object (i.e. shed wall).

Checking the wall thickness of the old bit, Carpo declared it good. It does not thin out significantly. In fact, the old end had worked out 30 thou greater diameter than the hole that it has to fit in (which was another good reason for starting again!). Bruce machined down the ‘slug’ so that it was an acceptable fit this time. The new end looks really smart.

Carpo annealed the other end, and we had a cuppa while it cooled. Then we cleaned both ends of the tube and the holes in the two tube plates. Tricky to see what you are doing when it is that high in the firebox.

Well there was no stopping us now, so in went the tube.

You can see how tight it was to get the tube under the superheater header. Some waggling was needed to get it beneath a cross-member at the firebox end, too.

… and out it comes:

Carpo trimmed the ends, and then started swaging.

Swages - below.

It all went very well at the firebox end …

It was more troublesome at the smokebox end, partly because of the confined space, and partly because the swage could have done with being fractionally bigger.

Nevertheless, after some fiddling & persuasion, the front end was done, too.

We started filling the boiler with water and adjourned for a cuppa. Carpo subsequently reported (at 6pm):

“As I write this we finally have a quarter of a glass of water - ideally I would like a full glass before I switch off the tap this evening so hopefully not too long now.

You will be pleased to know that currently all is dry.”

Tuesday 8th

Well, Carpo just couldn’t wait! I popped in during the morning to take a new clock (our old one died)

and some cardboard trays for boot scrapers, and there he was: in the cab, pumping up the pressure!

It was at 70 psi by 11 am and no sign of leaking tubes.

He later reported:

“I am pleased to report that upon inspection this morning there was no sign of any leaks from either

end of the replaced tube or indeed any other tube. I then modified the gauge frame adaptor to

accept a smaller hose to allow connection of the hydraulic pump. However having spoken to Ray Lee we agreed the first course of action was to put in my adaptor plug and use compressed air to take

the boiler up in pressure to see what effect that might have. I am delighted to report that following

two hours under pressure at 100 psi no leaks were seen at all.”

Wednesday 9th

Today was a bit of a waiting game - not a lot we could do until the boiler inspector comes on Thursday. The plan is then to demonstrate no leaks at 100 psi (cold), followed by hastily draining the boiler and removing all inspection plugs and mud-hole doors to enable him to inspect the innards.

Bruce had found a 6 metre length of reinforced hose. We had talked about using flexible hose for cleaning out boiler tubes several times before, and here was a chance to test the theory. Our initial design had been lengths of copper pipe, which worked well except that it is awkward attaching & removing lengths as the pipe goes in & out of the tubes; and some tubes are inaccessible with the rigid pipe.

So, Bruce & I clambered into the smokebox, and I tested the ease of getting the hose into various awkward tubes - no probs! Bruce then checked the attaching of this to the end of our hoover’s hose, and has now gone away to make a small cutting piece to fit in the business end.

Brian & Dixie shinned up a ladder and removed the brass bonnet from the safety valves.

Looking for things to do: One thing that I had noticed, but not got round to doing anything about,

was paint blistering up & down the beading around the cab front.

Clearly, there was a significant rust build-up underneath the beading and it deserved some attention. Brian and Dixie tackled it to begin with. Needle-gunning and then wire-brushing revealed quite a lot of rust. The left-hand side was worst, where the rust had opened up the beading, which was springing loose at the bottom.

A chap who was working on the new wagon kindly did a tack-weld for us, which held the bead steady (but also burnt through the thin cab side panel!). I found a tin of filler … but the hardener had gone AWOL, so Gil pootled off to Winchcombe to borrow some filler from Fred who uses it on the siphon restoration. The chaps then cleaned up the area and applied a first layer of filler.

Meanwhile, I had adjourned to our container to complete more boot scrapers.

Thursday 10th

Bruce arrived first and got everything ready. Meanwhile, Carpo demonstrated the boiler under pressure to the inspector. This was declared good, and pressure was released, followed by draining the boiler.

Gil arrived, and the two of them removed the safety valves and then moved on to removing boiler plugs.

Viz left: Bruce fits spanner to plug; Gil applies brute force to undo it.

I removed mudhole doors. A wire loop screws into the door’s stud so that the door cannot go

walkabout on its own inside the boiler. Then I helped remove other plugs.

The inspector inspected the inside of the firebox; peered into various holes, and seemed quite pleased with what he saw. So, the next steps are to wash the boiler out; box it up again (i.e. plug the holes) and then do a steam test. But not this week! Saturday is cancelled!

Roger

Gil, Bruce and I joined Carpo with a view to finishing off making the new boiler tube. When we looked at the end that we had opened out on Saturday, we decided that it was good, but it wasn’t Carling. So, we cut it off and started again!

This time, Carpo heated a narrower area of tube before we hit it, thus avoiding any deformation above the bit we were trying to open out. Also, we did the hitting on the horizontal, which gave us much better control over the angle of the pipe (90°) against the immovable object (i.e. shed wall).

Checking the wall thickness of the old bit, Carpo declared it good. It does not thin out significantly. In fact, the old end had worked out 30 thou greater diameter than the hole that it has to fit in (which was another good reason for starting again!). Bruce machined down the ‘slug’ so that it was an acceptable fit this time. The new end looks really smart.

Carpo annealed the other end, and we had a cuppa while it cooled. Then we cleaned both ends of the tube and the holes in the two tube plates. Tricky to see what you are doing when it is that high in the firebox.

Well there was no stopping us now, so in went the tube.

You can see how tight it was to get the tube under the superheater header. Some waggling was needed to get it beneath a cross-member at the firebox end, too.

… and out it comes:

Carpo trimmed the ends, and then started swaging.

Swages - below.

It all went very well at the firebox end …

It was more troublesome at the smokebox end, partly because of the confined space, and partly because the swage could have done with being fractionally bigger.

Nevertheless, after some fiddling & persuasion, the front end was done, too.

We started filling the boiler with water and adjourned for a cuppa. Carpo subsequently reported (at 6pm):

“As I write this we finally have a quarter of a glass of water - ideally I would like a full glass before I switch off the tap this evening so hopefully not too long now.

You will be pleased to know that currently all is dry.”

Tuesday 8th

Well, Carpo just couldn’t wait! I popped in during the morning to take a new clock (our old one died)

and some cardboard trays for boot scrapers, and there he was: in the cab, pumping up the pressure!

It was at 70 psi by 11 am and no sign of leaking tubes.

He later reported:

“I am pleased to report that upon inspection this morning there was no sign of any leaks from either

end of the replaced tube or indeed any other tube. I then modified the gauge frame adaptor to

accept a smaller hose to allow connection of the hydraulic pump. However having spoken to Ray Lee we agreed the first course of action was to put in my adaptor plug and use compressed air to take

the boiler up in pressure to see what effect that might have. I am delighted to report that following

two hours under pressure at 100 psi no leaks were seen at all.”

Wednesday 9th

Today was a bit of a waiting game - not a lot we could do until the boiler inspector comes on Thursday. The plan is then to demonstrate no leaks at 100 psi (cold), followed by hastily draining the boiler and removing all inspection plugs and mud-hole doors to enable him to inspect the innards.