Monday 4th Jan

Having

failed to complete the sand box on Saturday, it irritated me so much

that on Monday I trotted off to Todders and fixed the thing! I drilled

through the split-pin hole and got that fixed. Then there was a linkage

from there to the operating lever - again, a split-pin played up! I

got a new pin, cut it down to size and fitted that, too. The delivery

pipe was the last bit to fit. Then I tested the whole mechanism, and it

works (well, it left a little pile of sand on the rail when I turned it

to 'open'). Enough for today!

Wednesday 6th

I

didn't see much of Bruce today - he spent all day (apart from tea break

& lunch) in between the frames, reaming out the holes in the pony

truck bridge piece. By end of play he has got the top hole to within 2

thou' of being perfectly circular. We now need the new

to-be-manufactured pin to be completed and delivered so that great care

can be taken in matching the hole to the pin.

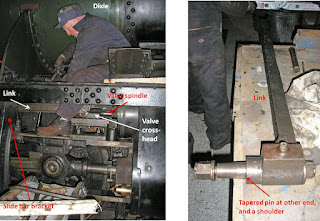

Gilbert

& Dixie worked on removing the RHS valve and link rod to the

rocking shaft. The whole rocking shaft unit appears to move when the

loco is in service. This might be due to the securing bolts not being

of the "fitted" kind; or it might be due to play in the pin that

connects link to rocker arm; or play in the brass bearing of the rocker;

or a combination of some/all these things! So, it has to come apart.

Separating the valve spindle from its little cross-head was the first

challenge. That took all morning (because of a taper). Then there was

not enough room to release the link from the cross-head (because the

slidebar bracket is in the way); which meant that the spindle had to be

pushed through (and that meant belting it with a 'persuader'!), to push

the link back to the frame and pull its tapered pin free at the other

end! All was achieved by end of play.

Bruce

mentioned that the brass bonnet was only held on by a couple of bolts.

It had been fitted in a hurry by the loco crew - I can't quite remember

why we hadn't had time to replace it. I speculated on why all bolts

had not been fitted … and I leave it to you to work it out from the

photo! :-)

While

up there, I remembered that the safety valves have been reported as

blowing off at 215 (instead of the correct 225 psi). John had noticed

that it is the rear one that blows at 215, so we aim to adjust the

spacer before she goes back into service.

John

G helped me take our display board down (from the car park), ready for

it to be cleaned and re-done for the 2016 season. Then John tackled the

surface rust that had formed on all of the coupling and connecting

rods. He used wire wool plus oil to clean them and give some

protection.

Saturday 9th

We

set Brian on steam-cleaning things. There were a couple of sections of

running board that were really grotty, and I unbolted two more for

Brian to clean. Funny, though, there seemed to be more to clean than we

had removed … the Dinmore Manor group spotted Brian with the steam

cleaner, and started adding their own bits to his pile!

David

brought two "dishes" to fit on the lubricators for the pony. The

original ones were of the wrong type- too small. Bruce assembled one,

but we didn't fit them on.

Bruce

and John T spent much of the day examining the pony axleboxes. John

checked the bearing lubrication, and then assessed what material is

required for two strips per box to hold them in position. Bruce

measured various components to work out exactly what needs to be done.

Adey [Loco Dept] removed all of the tender brake blocks with a view to machining up the new ones to fit.

Gilbert & David concentrated on the RHS valve, finally getting it out by the end of the day.

I

began by removing one of the bolts that fixes the rocking shaft unit to

the frames. We think these should be fitted bolts, and they are not.

David & Gil discussed the best way to make new bolts to suit. Brian

removed the top cover from the rocking shaft so that the bearing shells

can be examined for wear.

Finally,

I went inside the firebox to inspect the nuts & rivets around the

grate area. All seem OK. I cleaned these up and applied aluminium

paint (750 degree heat tolerant), though there was no sign of the paint

that I applied last year, so whether it does any good …

There is now a list of outstanding issues from the loco report card, most of which we shall address in the next six weeks.

Roger

No comments:

Post a Comment